-

在线咨询

在线沟通,请点我在线咨询 -

咨询热线:

13501008385 -

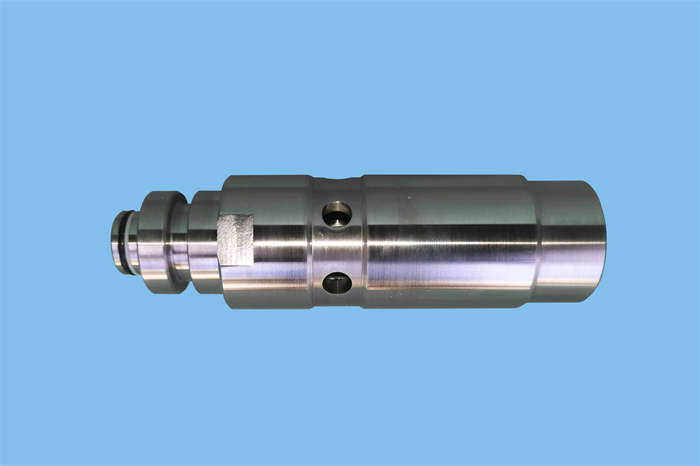

• 材质:不锈钢

• 公称压力:30-55MPa

• 公称流量:500-1000L/min

• 接口:M42×2、M40×1.5、DN20、DN25、DN12

• 特点:采用尾部充气方式,使安全阀充气更简便,开启压力灵敏度更高,寿命更长。

产品咨询:

氮气安全阀是一种保护用阀,它的启闭件受外力作用下处于常闭状态,当设备或管道内的介质压力增高,超过规定值时自动开启,通过向系统外排放介质来防止管道或设备内介质压力超过额定数值,从而达到保护设备或系统的目的。

一般安装在压力容器、受压管道及连接管道上。在液压支架上,氮气安全阀一般用在立柱千斤顶上,当千斤顶内压力超过整定压力时,安全阀开启,释放压力,保护千斤顶。

1)此氮气安全阀与普通的弹簧安全阀最大不同之处,是利用填充氮气代替传统的弹簧作用,可克服弹簧的疲劳、断裂等缺点,使安全阀的灵敏度、寿命大大提高。

2)此氮气安全阀在第一代侧面充气氮气安全阀的基础上,经过改进设计,采用底部充气方式,充气更简便,充气口密封更可靠,不易发生漏气的问题。

3)在冲击压力和运动速度变化下不会发生挤隙,撕裂,爬行和干磨生热的现象,密封性能可靠。

• Material: stainless steel

• Nominal Pressure: 30-55mpa

• Nominal Flow: 500-1000l /min

• Interfaces: M42×2, M40×1.5, DN20, DN25, DN12

• Features: the tail inflation method is adopted to make the safety valve easier to inflate, with higher opening pressure sensitivity and longer service life.

Product Consultation:

Nitrogen with valve relief valve is a kind of protection, the opening and closing pieces under the action of external force in a normally closed state, when the equipment or piping within the medium pressure increase, more than a specified value automatically when open, through a discharge medium system to prevent the pipeline or equipment within the medium pressure more than the rated value, so as to achieve the purpose of the protection device or system.

Generally installed in the pressure vessel, pressure pipe and connection pipe. On the hydraulic support, nitrogen safety valve is generally used on the vertical jack. When the internal pressure of the jack exceeds the setting pressure, the safety valve is opened to release pressure and protect the jack.

1) the biggest difference between this nitrogen safety valve and ordinary spring safety valve is that the filling nitrogen replaces the traditional spring action, which can overcome the spring fatigue, fracture and other shortcomings, and greatly improve the sensitivity and life of the safety valve.

2) this nitrogen safety valve is based on the first generation side gas-filled nitrogen safety valve. After an improved design, it adopts the bottom gas-filled mode, which makes it easier to inflate, more reliable to seal the gas-filled mouth and less prone to air leakage.

3) under the change of impact pressure and movement speed, there will be no squeezing, tearing, crawling and dry grinding to generate heat, and the sealing performance is reliable.